Many businesses choose industrial epoxy flooring because of its strength and flexibility. This type of flooring provides excellent durability and can resist chemicals and traffic. Plus, it looks cool and modern.

In this article, we will discuss the different types of industrial floor coatings. You’ll learn about their benefits and features. You should choose your flooring wisely and based on your own needs for the business. With the right information, you can make an informed decision that suits you well. This will ensure your flooring meets your requirements and enhances your space. Let’s dive in and explore the options available for industrial epoxy flooring!

Epoxy Floor Painting

Epoxy floor painting is a great choice for industrial spaces. It uses a special type of resin that creates a strong, durable surface. This coating protects floors from heavy wear and tear. It’s also UV stable, which means it won’t fade in sunlight.

One of the best things about epoxy industrial flooring is how easy they are to clean. It means how crazy it is that oil and chemical spills are not seeping through the coating? This makes maintenance simple and stress-free. You can wipe up messes without worrying about any damage even for a second.

Compared to polished concrete, epoxy floors offer the ultimate durability. The process of installing them involves mixing resin with a hardener. This combination forms a tough surface that lasts for years. Here, if you want the best result, you should consider proper preparation of the concrete.

Benefits of industrial epoxy flooring

Epoxy flooring offers many advantages for businesses. First, it provides higher resistance to harsh chemicals. This means your floor won’t get damaged easily.

The durability of epoxy makes it last for years and saves you money. Cleaning is a breeze thanks to its low porosity. You can maintain a tidy workspace without much effort.

Epoxy floors also brighten up factories and warehouses so that you could enjoy the good environment that lasts a lot. They meet safety standards with slip resistance, so your workers can work without any hazards, safe and sound. Plus, they resist spills from food industry items like citric acids and fats.

Applications of industrial epoxy flooring

Industrial epoxy flooring is versatile and suitable for many settings. It works great in factories and warehouses, so you can have a strong surface for your heavy equipment. You can also use it on walls for extra protection.

Mechanical workshops benefit from epoxy floors, because they can withstand spills and stains. Aircraft hangars require durable flooring, and epoxy meets those needs perfectly. Treatment plants also find epoxy useful due to its chemical resistance.

In commercial kitchens, cold rooms, and freezers, epoxy flooring helps maintain cleanliness. Its easy-to-clean surface makes it ideal for food preparation areas. Food manufacturing plants also rely on epoxy to handle spills from ingredients.

Retail outlets can enhance their appearance with bright and durable epoxy floors. This flooring solution is not only practical but also visually appealing.

The service industry, including bars and restaurants, benefits from epoxy’s slip resistance. This ensures safety for both staff and customers.

Finally, offices can use epoxy flooring to create a modern and professional look. Its durability means less maintenance and long-lasting results.

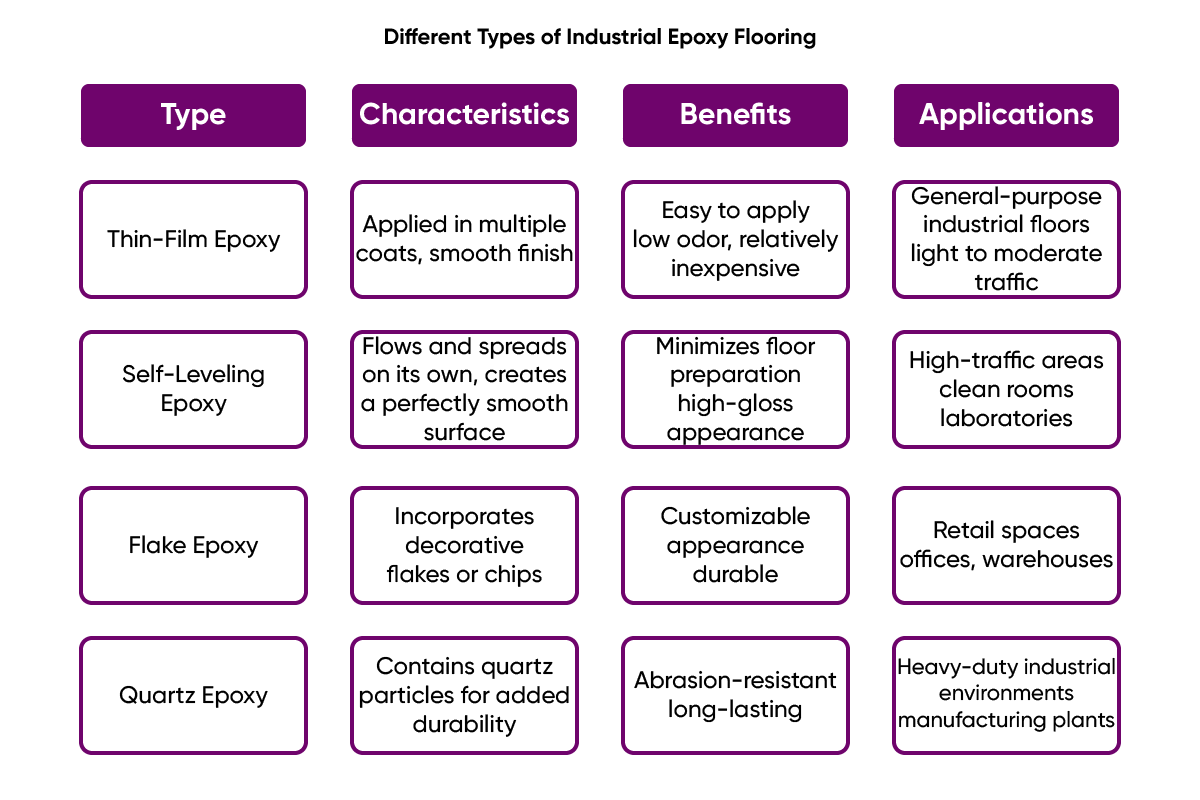

Types of Industrial Epoxy Flooring

Choosing the right industrial epoxy flooring is essential for your space. There are several types available, each with unique features. These are the ones below:

- Thin-Film Epoxy is a popular option for a smooth finish. It’s applied in multiple coats to create a sleek surface. This type is easy to apply and has a low odor. It’s also budget-friendly. So this will ne a great choice for many applications.

- Self-Leveling Epoxy is perfect for achieving a flawless surface. It flows and spreads on its own. This makes the finish uniform. This type reduces the need for extensive floor preparation and offers a high-gloss look.

- Flake Epoxy adds a decorative touch to your floors. It incorporates colorful flakes or chips. With these extra options, you can create the most attractive appearance for space. This type is highly customizable and allows you to design unique patterns that match your style.

- And last but not least, Quartz Epoxy. This is known for its durability and resistance to wear. It’s ideal for high-traffic areas, providing excellent performance over time. This option is tough enough to handle heavy loads and spills.

Here is a table to compare different types of industrial epoxy flooring:

Choosing the Right Industrial Epoxy Flooring

Selecting the right industrial flooring is important for your business. Start by considering traffic. Think about how much foot and vehicle traffic the floor will face. High-traffic areas need more durable options. Next, look at the chemicals in your environment. Different epoxy types resist various chemicals, so choose wisely. If your area handles harsh substances, opt for a more resistant flooring.

Aesthetics also matter. Decide how you want the floor to look. Some epoxy options allow for custom designs and colors. A visually appealing floor can enhance your workspace. Finally, consider your budget. Determine how much you can spend on the project. While some options may be more expensive, they could save you money in the long run. By evaluating these factors: traffic, chemicals, aesthetics, and budget, you can make an informed decision. Choosing the right industrial epoxy flooring contractors will ensure your space is functional and attractive. Take your time to select the best option for your specific needs.

The bottom line

Industrial epoxy flooring is a top-notch choice for commercial and industrial spaces. Its durability, chemical resistance, and low maintenance make it a standout option. Whether you’re dealing with heavy machinery, harsh chemicals, or high foot traffic, epoxy flooring can handle it.

FAQs

What is the difference between epoxy and polished concrete?

Epoxy flooring offers superior durability and chemical resistance compared to polished concrete. It also provides a more customizable appearance.

How long does it take to install industrial epoxy flooring?

The installation time for industrial epoxy flooring varies depending on the size of the area and the type of epoxy used. However, most installations can be completed within a few days.

Can I apply epoxy flooring over existing concrete?

Yes, you can apply industrial flooring over existing concrete. However, the surface must be properly prepared to ensure good adhesion.

How do I maintain epoxy flooring?

Epoxy industrial coating is easy to maintain. Regular sweeping and mopping are sufficient to keep the floor clean. Avoid using harsh chemicals or abrasive cleaners.

How long does industrial epoxy flooring last?

When properly installed and maintained, this flooring can last for many years. The lifespan will depend on factors such as traffic levels and exposure to chemicals.